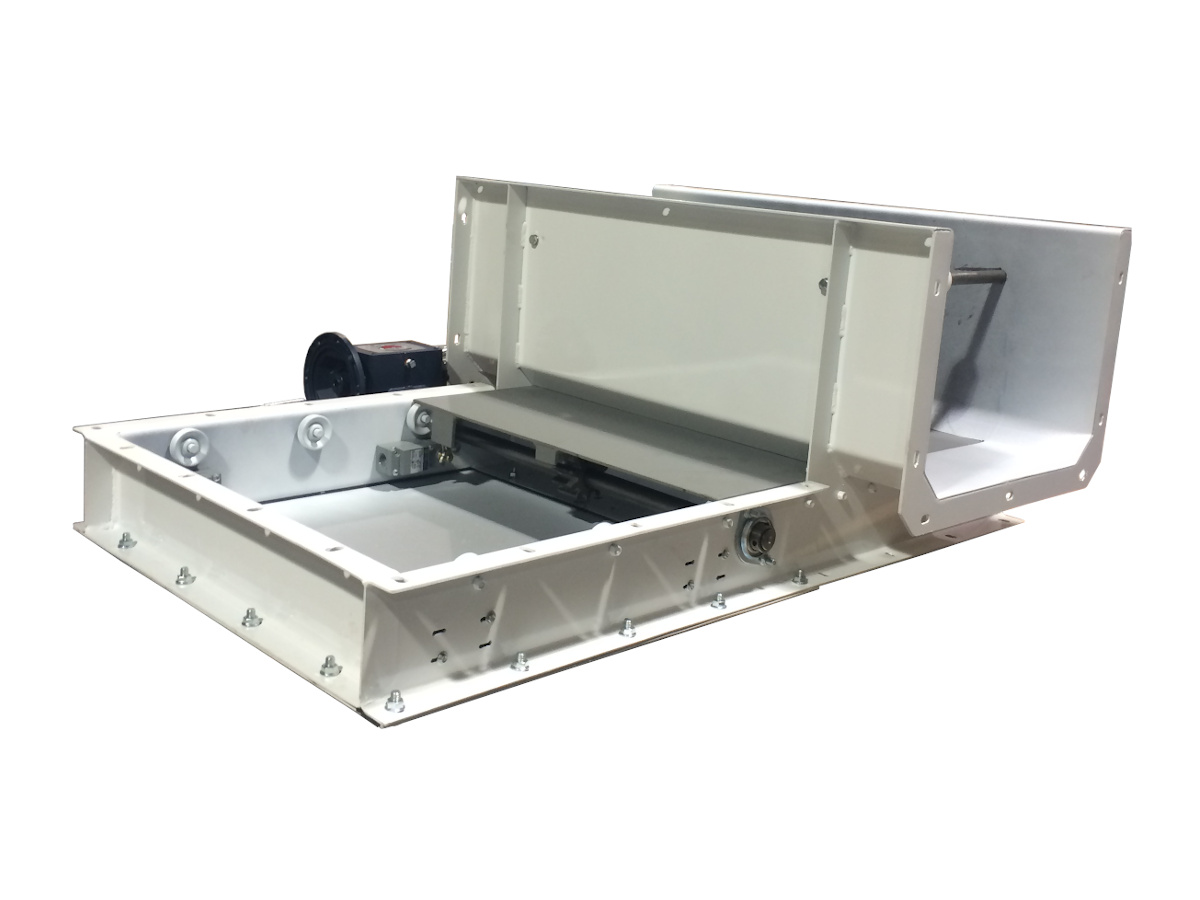

Our HV Series can effectively convey product up to 10 degree inclines utilizing an “En-masse” method. En-masse means that we can move up to 8” of product depth with 2” of flight. In some cases this allows us to move considerably more product with smaller box sizes, using less horsepower. This will save the customer on the initial cost of the equipment and operating expense for years to come. Our HV Series drag chain conveyors have a self-cleaning octagon shape bottom manufactured in one piece to prevent product build-up. Our conveyors are generally built wider vs taller. The taller the conveyor the longer it takes for product to discharge. Our conveyors typically have longer discharges again allowing more time for product to get out of the conveyor. This is a better alternative for intermediate discharges vs. a belt conveyor tripper with the same gentle handling result.

Features

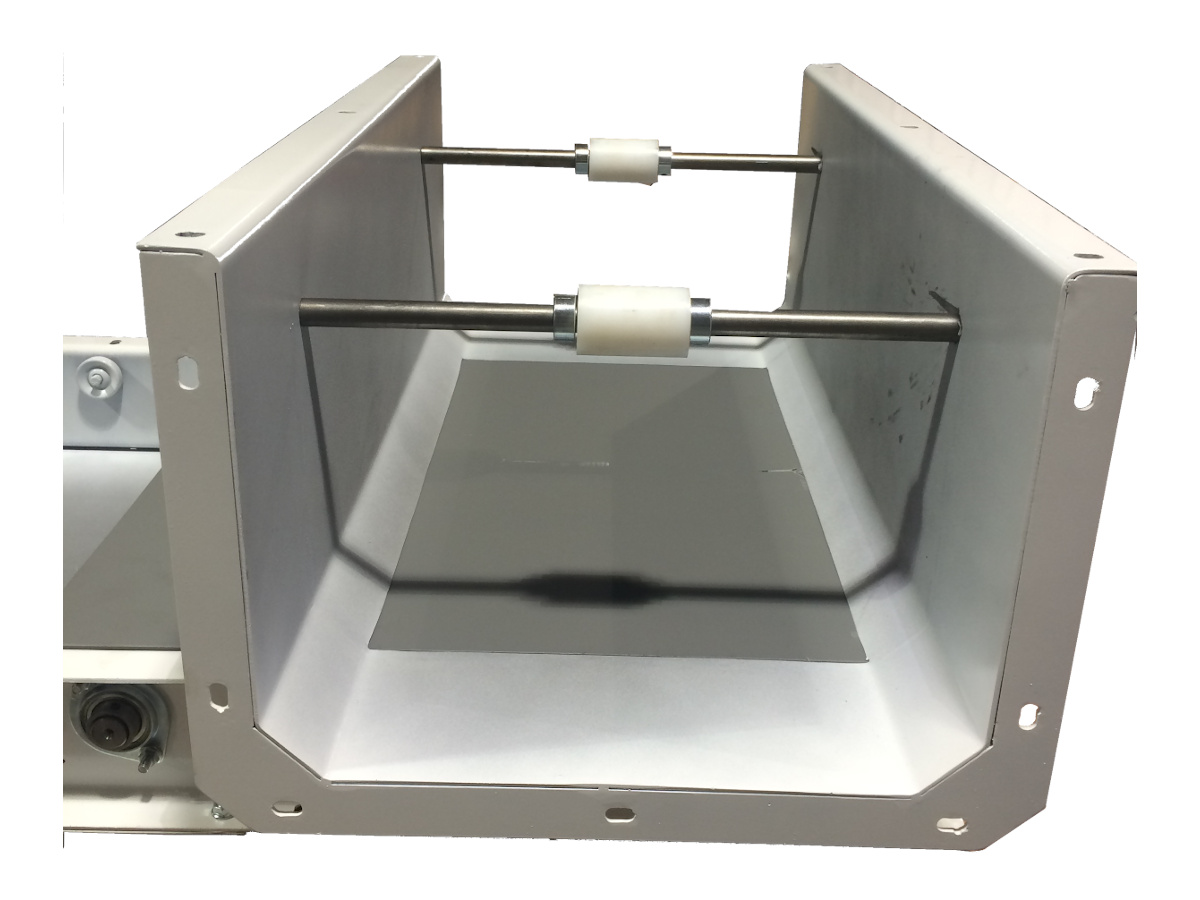

- Urethane chain wiper assembly

- Crafted flush mount slide gate is integrated as part of the bed section available in manual or electric control

- Chain, flights, & attachments are all on the same plane allowing effective wiping

- Slower chain speed with conservative product depth

- Long discharge openings allowing more time for the product to fall out

- Independent primary & secondary abrasion resistant, flexible chain wipers

- Contoured tail to minimize contamination

- 81XH Heavy Duty chain

- Flame cut hardened sprockets

- Galvanized ACME threaded rod take up assemblies

- Available in galvanized, primed & painted, stainless steel or powder coat on AR (Abrasion Resistant) steel

- 1/2” UHMW beveled flights

- Custom gauges & wear liners available

- Variable speed drives

- External mounted heavy duty pillow block head and tail bearings